Introduction of Jiaren chemical recycling technology

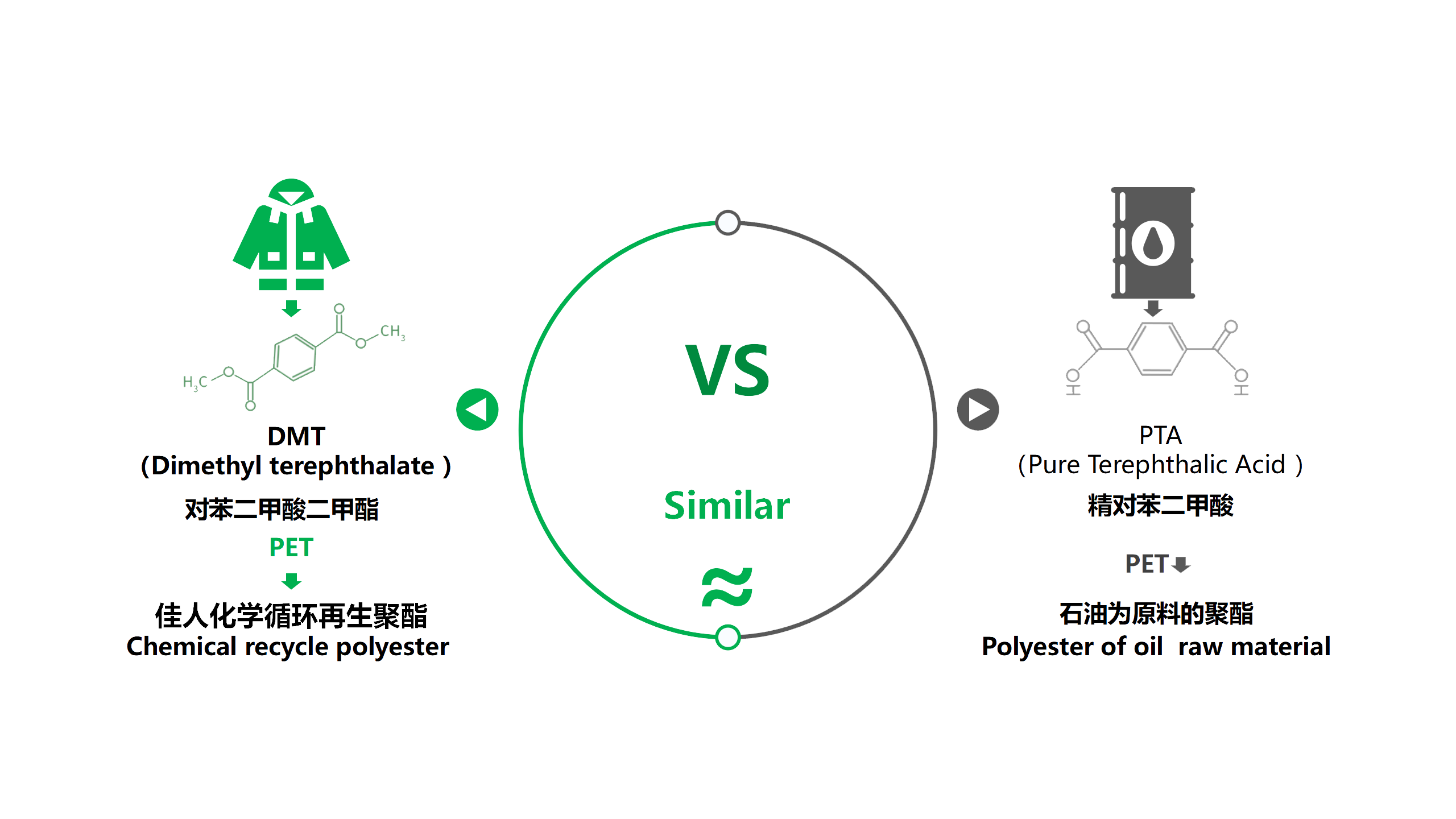

Through the process steps of pretreatment, depolymerization, filtration, separation, transesterification, purification and rectification, the new DMT material with a purity of up to 99.9% can be obtained.

Chemical technology to overcome the separation of blended materials in textile recycling, decolorization and impurity removal problems to ensure the uniformity and stability of recycled products. Chemical method has irreplaceable advantages of high purity and high value utilization. Its unique "small molecule depolymerization-polymerization technology" can convert difficult to recycle polyester into recycled polyester with similar quality to raw materials, which can be widely used in textile, automotive, food, daily chemical and electronic fields.